The latest version of the Australian and New Zealand Standard: Electrical Installations “Wiring Rules” (AS/NZS 3000:2018) has now been published, and will supersede AS/NZS 3000:2007. Updates to the Standard have been made to reflect new technologies, equipment, and installation techniques. This article explores some of the most significant changes presented in the standard, and how they will impact Australian electrical installations.

Note: This article aims to summarise sections of AS/NZS 3000:2018. Installation, design, or construction works should be carried out referring to AS 3000:2018 in its entirety.

1. Clarification of requirements for alteration and repair of electrical installations (Clause 1.9.3)

In addition to inclusion of ‘alteration’ and ‘repair’ in the definitions, further clarifications of what constitutes alterations and repairs have been provided in Clause 1.9.3 to aid electricians in understanding the distinction between the two and their associated requirements:

Alterations: Alterations to electrical installations shall not cause any portion of the original electrical installation, or connected electrical equipment, to: (a) carry excessive currents or sustain excessive voltages; or (b) be used in any manner that is not in accordance with AS/NZS 3000:2018.

Repairs: Repairs to existing electrical installations or their parts may be performed using methods, fixtures and fittings that were acceptable when that part of the electrical installation was originally installed or with methods, fixtures and fittings currently available as direct replacement, provided that the methods satisfy the fundamental safety principles of this Standard.

2. Clarification of mandatory RCD requirements for protected circuits, alterations and repairs

(Clause 2.6.3)

AS/NZS 3000:2018 specifies significant clarifications to the protection requirements of residual current devices (RCDs). Some of the most significant additions are as follows:

- Requirement for installation of RCDs in all final sub circuits in domestic and residential installations: RCDs with a maximum rated residual current of 30 mA are now required for all final subcircuits in domestic and residential installations, with the exception of carrying out exempt repair work (see below),

- Requirement for installation of RCDs in commercial and industrial installations: RCDs with a minimum residual current of 30 mA are now required for final subcircuits, rated 32 A or less, that are supplying socket-outlets, lighting, direct-connected hand-held equipment, and direct-connected equipment that presents increased risk of electric shock. These restrictions do not apply to repairs undertaken in accordance with this Clause (see below). Additional exemptions from this requirement includes cases where disconnection by an RCD could cause a danger greater than earth leakage current, or when an equipment has low risk of electric shock and installation of RCD can adversely affect the performance of the installation.

- Requirement for installation of RCDs with alterations to installations or replacement of switchboards: RCD requirements are applicable where switchboards are altered or replaced. In an alteration, RCDs are required for final subcircuits. RCDs are also required to protect socket-outlets added to an existing circuit, in accordance with the requirements for new subcircuits, in the part of the installation in which they are located. Where socket-outlets are added to an existing circuit and RCD protection is required, the RCD protection only needs to be fitted at the origin of the additional wiring. Where all circuit protection on a switchboard is replaced, additional protection by RCDs are required for the final subcircuits supplied by that board.

- Repairs exemption: Where a single item of electrical equipment (e.g. a socket-outlet or light) which is not RCD-protected is replaced with an equivalent item in the same location, an RCD can be installed on the affected subcircuit, but is not mandatory.

Clause 2.9 describes the requirements for protective equipment such as arc fault detection devices (AFDDs), which may be used to protect against the effects of arc faults in final subcircuits. AFDDs are required to comply with IEC 62606, and have a load current rating no less than that of the associated protective device. AFDDs are required to be located at the switchboard supplying the final subcircuit. The installation of AFDDs should be considered when carrying out alterations to final subcircuits in situations where existing wiring systems may significantly deteriorate.

This Standard does not require installation of AFDDs in Australia currently.

However, in New Zealand all final subcircuits with ratings up to 20 A will require protection by an AFDD if they supply locations with significant fire risk, locations containing irreplaceable items, certain historic buildings, or socket-outlets in school dormitories.

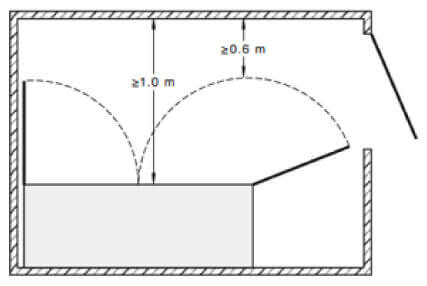

4. Enhanced requirements for switchboard installation and minimum clearances (Clause 2.10)

Clause 2.10 contains significant changes to switchboard installation requirements to provide sufficient access to switchboards. These changes include the following requirements:

- 1.0 m minimum distance from all faces of a closed switchboard that need to be accessible. In a domestic electrical installation this distance may be reduced to 0.6 m.

- Unimpeded space of at least 0.6 m around switchboards with switchgear doors in any position and with switchgear in a fully racked-out position.

- A minimum of two emergency exit paths, spaced well apart, where a switchboard:

- Is rated as a circuit with a nominal capacity of at least 800 A per phase, or

- Is more than 3 m in length

Exception: Where a clear space of at least 3 m is provided in front of the switchboard and its equipment (including its doors), only one emergency exit path needs to be provided.

- Openings or doorways should be at least 0.9 m wide by 2.2 m high to allow access to the switchboard room or enclosure where necessary.

- Where switchboards are located opposite each other, clearance shall be measured with all doors in the open position.

Figure 1: Access to switchboards – switchboard in corner position

Note that due to these requirements there may not be sufficient space for installation of inverters and batteries in switchboard rooms that have not been designed with additional clearance.

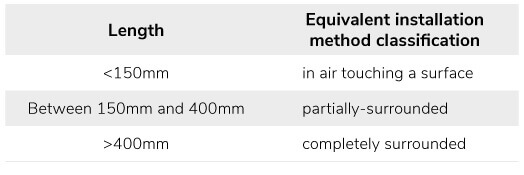

5. Improved installation safety for cables that pass through bulk thermal insulation (Clause 3.3.2)

Clause 3.3.2 now describes an additional external influence on wiring systems: thermal insulation. Clause 3.3.2.13 states that the rated current-carrying capacities of cables passing through bulk thermal insulation is to be calculated according to the length of cable passing through the insulation (in accordance with AS/NZS 3008.1).

6. Updated installation requirements for electricity generation systems (Clause 7.3)

Clause 7.3 has been updated to provide more guidance on installations with electricity generation systems:

Definition of stand-alone power system (SAPS): This concept has been redefined to accommodate renewable energy generation, i.e. photovoltaic arrays, wind turbines, and mini-hydro turbines.

Conditions for isolation: An inverter or regenerative supply source shall not be connected

downstream of the generating set changeover device. Exception: This requirement need not apply where control systems prevent backfeed to the generator.

Conditions for MEN connection: The neutral-earth connection (MEN connection) shall be made within the installation at the main switchboard. This may require disconnection of any neutral-earth connection within an electricity generation system, such as an engine-driven generating set.

7. New informative appendices (Appendices N, O, P, Q)

A number of informative appendices have been included in the 2018 version of AS/NZS 3000, which provide useful information contained within other Australian Standards. As they are not classified as normative appendices, the information is provided to help the reader understand the intent of the standard. These are as follows:

Appendix N – Electrical conduits (informative)

Containing information from AS/NZS 2053 ‘Conduits and fittings for electrical installations’ and IEC 61386 ‘Conduit systems for cable management’, this Appendix provides information regarding the use of appropriate cable conduit in electrical installations. It describes the marking and classification of cable conduit, and provides tables for conduit duty and temperature ratings.

Appendix O – Installation of Arc Fault Detection Devices (informative)

As described in previous sections of this article, where there is significant risk of electrical fire, it can be beneficial for electrical installations to include methods of minimising electrical fire risk. This Appendix provides guidance on the selection and installation of AFDDs to mitigate the risk of igniting an electrical fire in final subcircuits downstream of the arc fault detection device (AFDD). It refers to IEC 62606 ‘General requirements for arc fault detection devices’.

Appendix P – Guidance for installation and location of electrical vehicle socket-outlets and charging stations (informative)

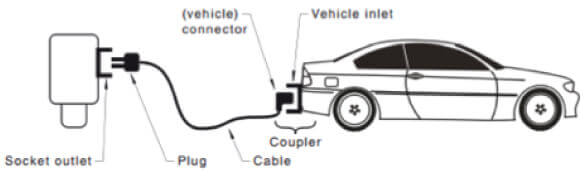

This Appendix has been included to provide guidance for: (a) circuits intended to supply energy to electric vehicles; and (b) circuits intended for feeding electricity from electric vehicles back into the supply system. This applies to off-board equipment including the vehicle connector for charging electric road vehicles, with a rated supply voltage up to 1000 V a.c. or up to 1500 V d.c. and a rated output voltage up to 1000 V a.c. or up to 1500 V d.c. It refers to IEC 61439 ‘Low-voltage switchgear and control gear assemblies’, IEC 62752 ‘In-cable control and protection device for mode 2 charging of electric road vehicles’, and IEC 62196 ‘Plugs, socket-outlets, vehicle connectors and vehicle inlets – conductive charging of electric vehicles’.

Figure 2: Connection of an EV to the a.c. supply utilizing a detachable cable assembly with a vehicle connector and a.c. supply connection to a socket-outlet

Appendix Q – D.C. circuit protection application guide (informative)

This Appendix describes the selection of circuit protection and switching devices operated on a d.c. supply that would be deemed to meet the requirements of this Standard. Among other topics, it describes requirements for arc suppression, switchgear typing, d.c. ratings, subcircuit wiring/fittings, switchboard locations, and inverters.

8. Additional minor changes

Finally, minor changes have been made throughout AS/NZS 3000:2018 which will affect how electrical installations are performed. These include:

- The date of initial certification at installation switchboards (Clause 8.4): The date of initial certification for an installation is now required to be available on-site, in the form of permanent, indelible marking on or at the main switchboard.

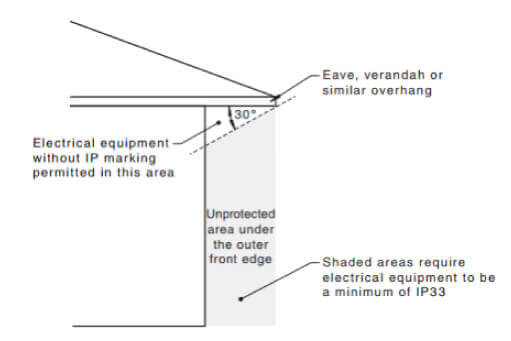

- New figures added and existing figures updated: Multiple changes and additions have been made to figures, e.g. where IP rated equipment is to be installed (see Figure 3).

Figure 3: Area under an overhang requiring accessories to be a minimum of IP33 (front view)

9. Keeping on top of changes in the industry

To assist PV installers in keeping on top of changes in the industry, like these necessary standards updates, GSES periodically releasing informative animations, subscribe to our channel here !