Large scale solar projects have seen tremendous growth in recent years, with notable projects including the 10MW capacity Greenough River Solar Farm in Western Australia and the 220MW Bungala Solar Power Project in South Australia. These projects require significant investment from system owners, and particularly for larger projects it is important to maximise financial return so that breakeven can occur as quickly as possible.

To achieve this, a common strategy is to maximise the energy yield of PV systems. There are a number of strategies which can be employed including the use of high-efficiency solar modules, locations with greater sunlight exposure, and oversizing PV arrays relative to their inverters. However, high-efficiency modules and array oversizing can be expensive and, in many cases, it can be more advantageous to employ PV tracking systems.

Tracking systems are mechanisms which enable PV modules or arrays to follow the position of the sun over time. In general, there are two types of tracking:

- Single-axis tracking: These systems tracks the sun’s movement along a single axis of rotation, either from east to west to track the horizon (i.e. azimuth angle) or north to south to track seasonal change (i.e. altitude angle). In single axis tracking the modules are adjusted periodically or continuously to optimise the incidence angle of the module surface for sunlight collection.

- Dual-axis tracking: These systems track along both horizontal and vertical axes. This means that panels can always be normal to the sun.

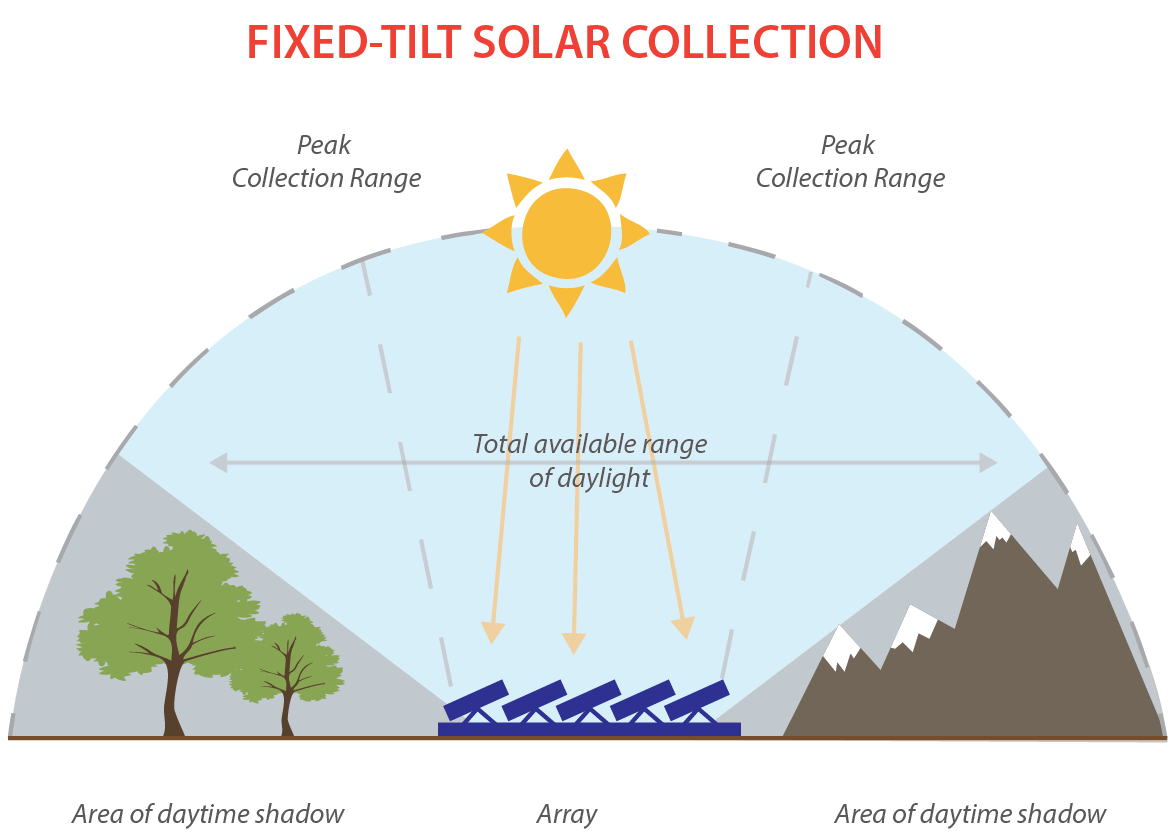

Figure 1: Comparison of fixed-tilt and rotational solar arrays (DCE SOLAR)

Figure 1: Comparison of fixed-tilt and rotational solar arrays (DCE SOLAR)

The main motivation for using a tracking system is to increase yield. According to industry literature, systems employing single-axis tracking can experience yield increases between 10% and 25% (Abbaraju, 2018) while systems employing dual-axis tracking can experience yield increases of greater than 40% (DEGER, 2018), relative to conventional fixed frame mounting. This is particularly important in systems where owners are seeking to maximise energy yield given a limited number of modules.

Modelling software,such as National Renewable Energy Lab’s (NREL) System Advisor Model (SAM), can be used to simulate tracking systems to assess the increase in system yield. For more information about SAM, visit: www.sam.nrel.gov

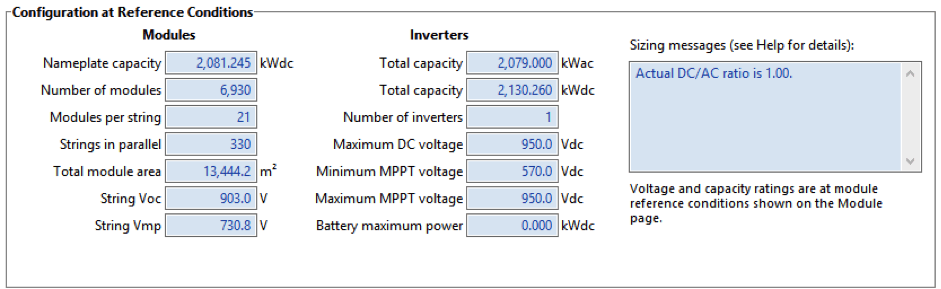

To demonstrate how modelling software can help decision making, GSES modelled an example project with a target generation of minimum 2.9 GWh/year, using a fixed-frame, single-axis tracker and dual-axis tracker and tabulate the resultant system requirements. The simulation was conducted using SAM, with the settings used for fixed frame system shown in Figure 2 below.

Figure 2 – Modelling a fixed frame system in SAM.

As shown in Table 1, the fixed frame system requires 6930 modules to produce 2.9GWh/year, while the single- and dual-axis tracking systems require 1218 and 1638 less modules respectively. Despite this, the land area requirements for both single- and dual-axis systems are greater than for the fixed frame system, with the dual-axis tracking system requiring more than double the land area needed for the fixed frame system. This is because a tracking array requires greater spacing than a fixed system to reduce inter-row shading when the sun is low, and thus needing more ground coverage.

Table 1 – Comparison of system requirements.

| Tracking System | Fixed Frame | Single Axis Tracking | Dual Axis Tracking |

| Array Size (kWdc) | 2085 | 1720 | 1590 |

| Number of Modules | 6930 | 5712 | 5292 |

| Yield (MWh/year) | 2,989 | 2,983 | 3,001 |

| Land Area Required (m2) | 22,257 | 26,709 | 51,395 |

| Approximate Cost ($Millions) * | $3.44 | $3.19 | $3.50 |

* NOTE: Pricing is based on sample market install rates only and does not consider land costs or ongoing operational costs.

Another factor that must be considered is the layout of the site. While a fixed frame installation can be arranged to suit the majority of site layouts, systems with tracking systems can be difficult to arrange, and can require complex earthworks, trenching, and cable management, This will naturally increase installation costs and can reduce the project’s financial viability.

Many solar farms around Australia have implemented single-axis tracking due to the increased performance over fixed frame systems, and the smaller land requirements when compared to dual-axis tracking. Some examples of Australian solar projects that have utilised single-axis or dual-axis tracking are described below.

1. Moree Solar Farm

Figure 3 – Moree Solar Farm

(source: ARENA)

Located in Moree, New South Wales, this 70MW solar farm uses single-axis tracking technology. The main motivation for selecting single trackers over dual trackers was due to the fact that the technical design of single-tracking systems is less complicated (FOTOWATIO RENEWABLE VENTURES). The expected output of the system is around 150,000MWh per year.

2. Oakey 1 & 2

Figure 4 – Oakey Solar Farm

(source: Canadian Solar)

Stages 1 and 2 of the Oakey Solar Farm, located in Queensland, will have a combined capacity of 100MWdc and are expected to generate 195,200MWh annually. The main motivation for using the single axis tracker is to enable higher yield, given the suitability of the site layout.

3. UQ Gatton Campus

Figure 5 – Gatton Solar Research Facility dual axis tracking array

(source: The University of Queensland)

This 684kWp array commissioned in 2015 utilises a dual axis tracker. This system was built as a research project for new and existing solar projects. The main motivation for selecting dual axis was to assess system yield in comparison to fixed and single-axis tracking.

In general, selecting a tracking system will increase the yield of the PV system. However, this brings increased technical complexity and could also lead to greater land area requirements. In this article, a basic analysis showed that the single-axis tracker produces the lowest A$/watt capital expenditure for a given required yield. However, other factors must be considered, including the site layout, earthworks, trenching, and cable management. In all cases, a detailed modelling should be carried out before deciding on a tracking or fixed system.

References

- Abbaraju, A. D. (2018). OPTIMIZING YOUR ENERGY YIELD. Nextracker.

- DCE SOLAR . (n.d.). docs/Single-Axis-Tracking-Systems.pd. Retrieved from A Dcesolar Website : https://www.dcesolar.com/docs/Single-Axis-Tracking-Systems.pdf

- DEGER. (2018, 08 09). PRODUCT OVERVIEW: DUAL-AXIS DEGERTRACKER. Retrieved from A Deger Web site : https://www.degerenergie.de/en/index.html

- FOTOWATIO RENEWABLE VENTURES. (n.d.). LESSONS LEARNED IN THE DEVELOPMENT OF MOREE SOLAR FARM.