Solar installers/designers are experiencing an increase in battery enquiries in recent months as the summer bushfires and the COVID-19 pandemic brings energy autonomy to the forefront of homeowners’ minds. Even though sizing a battery energy storage system for a residential site appears to be simple on the surface, there is more to selecting a battery for a home than simply matching the expected kilowatt-hour usage with the battery capacity. How energy is used in a home is just as important as how much energy is used.

There are two components to a battery’s size: storage capacity – the amount of energy which the battery can store and provide after one full charge, and power rating – how much power it can take in or discharge at any one time. A battery’s power rating is important for it to meet its expectations.

Power vs Energy

It is important to understand the difference between power and energy. Energy describes how much electricity a battery charge or discharge over a period of time, often measured in kilowatt-hours. Power describes how much demand (loads) a battery can service at any one time. In a battery, power correlates to the discharge current of the battery. For example, if a battery can supply a very high continuous discharge current (i.e. it can supply a lot of power) but has a low capacity (i.e. it can supply only a little energy) it could power many loads at the continuous discharge current limit of the battery, but only for a short period of time.

This article addresses how the installer should select a battery to match its intended usage’s power demand. It assumes that the installer knows how to select the battery capacity for the energy requirement. It also assumes that the installer knows how to calculate the continuous discharge current of the battery given the power demand taking into account inverter efficiency.

There is also a third consideration, the battery’s ability to provide short duration current to the inverter for starting loads such as motors, which assumes the inverter has been sized correctly for surge demand.

What is the battery supposed to do?

The power requirement of the battery is tied to the function it is expected to perform. Is it supposed to provide full backup power or backup power to specific loads during blackouts? Is it supposed to offset all the energy consumed in the evening during peak time of use tariffs? After identifying what the battery will be used for, the maximum power, and therefore the maximum continuous discharge current the battery must deliver, can be calculated. The battery must also be able to provide high, short duration current for loads that have a surge demand.

It is also important to realise that there is a difference between Lead Acid batteries and Li Ion batteries. The actual storage capacity (in kWh) of the Li Ion battery generally stays the same, independent of the discharge current. For example, if the usable battery capacity is 10kWh and the discharge is 5kW then it will last 2 hours and if it is discharged at 2kW it will last 5 hours.

However, lead acid batteries ratings are typically specified in Ah and they have different Ah capacity depending on the discharge current. The higher the discharge current the lower the Ah capacity for the battery. It is important to determine the discharge current and duration when selecting the battery capacity.

The maximum continuous current of a battery is the current that can be discharged over a specified period of time without damaging or reducing the performance of the battery. The continuous discharge current of the battery needs to be higher than the loads supplied via the inverter to prevent the battery voltage dropping to a level where the battery management system (BMS for Li Ion and Inverter for Lead Acid battery) disconnects the energy supply from the battery, or worse, damage the battery.

The battery’s maximum charging rate can also be important for performing the battery’s function. For example, if a battery is supposed to charge fully from a PV array over a sunny day, the battery’s charging current must be high enough such that if it is sunny, it can take up all the excess charge from the PV array

This prevents nasty surprises for the customers — a fully charged battery that is adequately sized will be able to power all the loads it was designed to supply, and charge from the PV array throughout the day. If the battery is undersized for power demand, the excessive current draw will: reduce the battery voltage to a point where the battery is disconnected from the inverter, permanently damage the battery, or prematurely degrade the battery. For some battery types the discharge current might stop at the maximum current which, being smaller than required, will mean the system is not able to offset the desired amount of energy. If the battery is undersized for recharging capacity, it might not be able to accept all the charge and then not have enough energy for its intended purpose.

Sizing battery to supply power demand

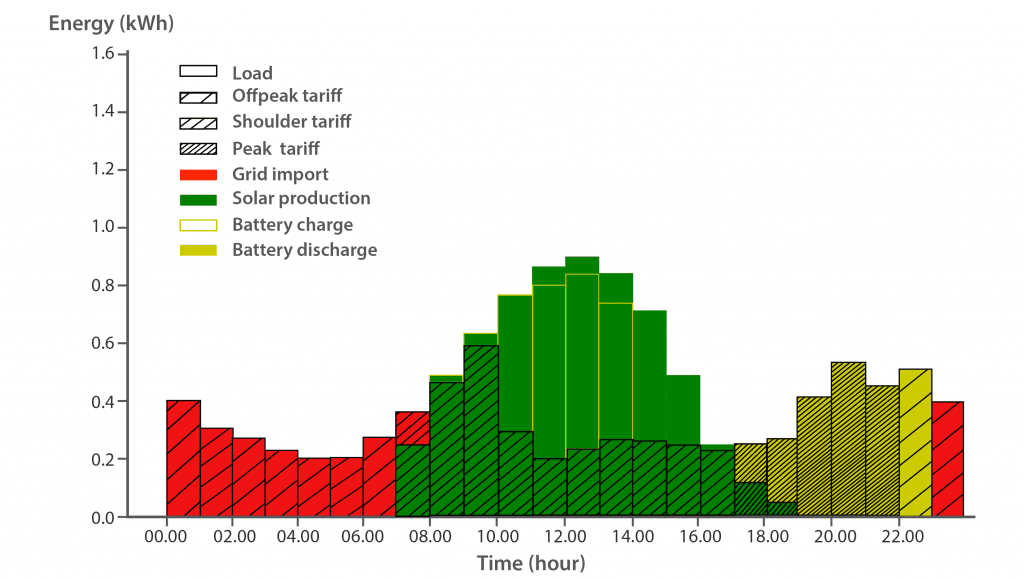

If the battery’s primary purpose is to meet evening peak demand, the battery’s continuous power must be matched to the demand onsite, or some power will be drawn from the grid. For example, in the load profile below (Figure 1), a battery with a 600W continuous discharge rate was fully charged throughout the day, and discharged fully throughout the evening. Between 8pm and 9pm, the average demand was nearly 800W. This means that 200W of power needed to be drawn from the grid.

Figure 1: A battery with 600W continuous discharge rate is fully charged from PV during the day, and fully discharged during the evening.

In the case where there is a grid outage, the battery management system might simply disconnect to protect the battery if it cannot provide the current required to supply the backup circuit or, if it can supply the current for a short time, the battery voltage might drop to a level where the battery management systems disconnects the battery from the load. Some loads will need to be switched off or excluded from the backup circuit to ensure the battery operates within its specified parameters. It is essential to evaluate the appliances and loads connected to the backup circuit and explain both the power and energy limitation of the battery system to avoid disappointed customers and potential complaints.

Sizing battery for the PV Array

If a PV array is onsite, there can be a few reasons a battery is sized with the PV array’s output in mind. If a battery’s primary function is to take up excess solar, it must be sized such that it can take up the excess PV generation at a rate fast enough to avoid PV export.

For example, in the load profile below (Figure 2), a battery with a 600W continuous charging rate is charged fully throughout the day, and discharged fully throughout the evening. Note that it can only take up to 600W of continuous charge. As the excess PV generation is more than the battery’s charge rate, some PV generation was still exported between 10am and 1pm, before the battery was fully charged.

Figure 2: A battery with 600W equivalent of charging rate is fully charged from PV during the day, and fully discharged during the evening. Note that there is some excess PV generation that the battery was unable to absorb.

Solar resource varies with the season and the weather, so there will likely be days where the solar generation is exported to the grid or curtailed, and there will always be overcast days where the PV array contributes very little to battery charging. The user’s day-time energy usage will also affect how much excess energy from the PV array is available for battery charging. If this system is expected to provide backup power during grid outage, some reserve capacity should be set aside.

Managing customer expectations

It is likely that the customer never had to think beyond the quarterly kilowatt-hour consumption value on their bill. For these customers, it can be helpful to explain the difference between power demand and energy consumption.

When sizing a battery, go beyond the energy bills! It can offer high level insight into seasonal usage trends, but does not offer reliable information on the power demand of the site. The most reliable way to measure demand is either via interval consumption data recorded by a smart meter onsite, or datalogging the site’s consumption.

A battery system which is mismatched for power delivers less energy savings for the customer and can fail the customer when they need it the most – during grid outage. However, high discharge current correlates with bigger and hence more expensive batteries. It is therefore important to understand what the customer really needs and trim out the excess. Energy efficiency measures can significantly reduce power demand and load shifting from the evening to the daytime will reduce both energy and power demand on the battery, saving the customer significantly on battery system upfront cost while meeting all their needs.

Communication is key – the installer is the bridge between the customer and their system and should educate the customer on how their system works. If the customer understands the relationship between the PV array and the battery, they will be able to have a reasonable expectation of the PV array’s contribution to battery charging. A satisfied customer will understand the limitations of the product and operate it in such a way that it outlasts its warranty.

GSES’s Solar Battery System Fundamentals online course covers all the basics of a residential battery system. Are you an accredited solar designer or installer looking to become accredited in battery storage as well? Check out our Grid-Connected Battery Storage Systems course. GSES also offers consultancy services from battery feasibility studies to independent inspections. For more details contact the owner’s engineer team at info@gses.com.au or give us a call at +61 2 9024 5312.

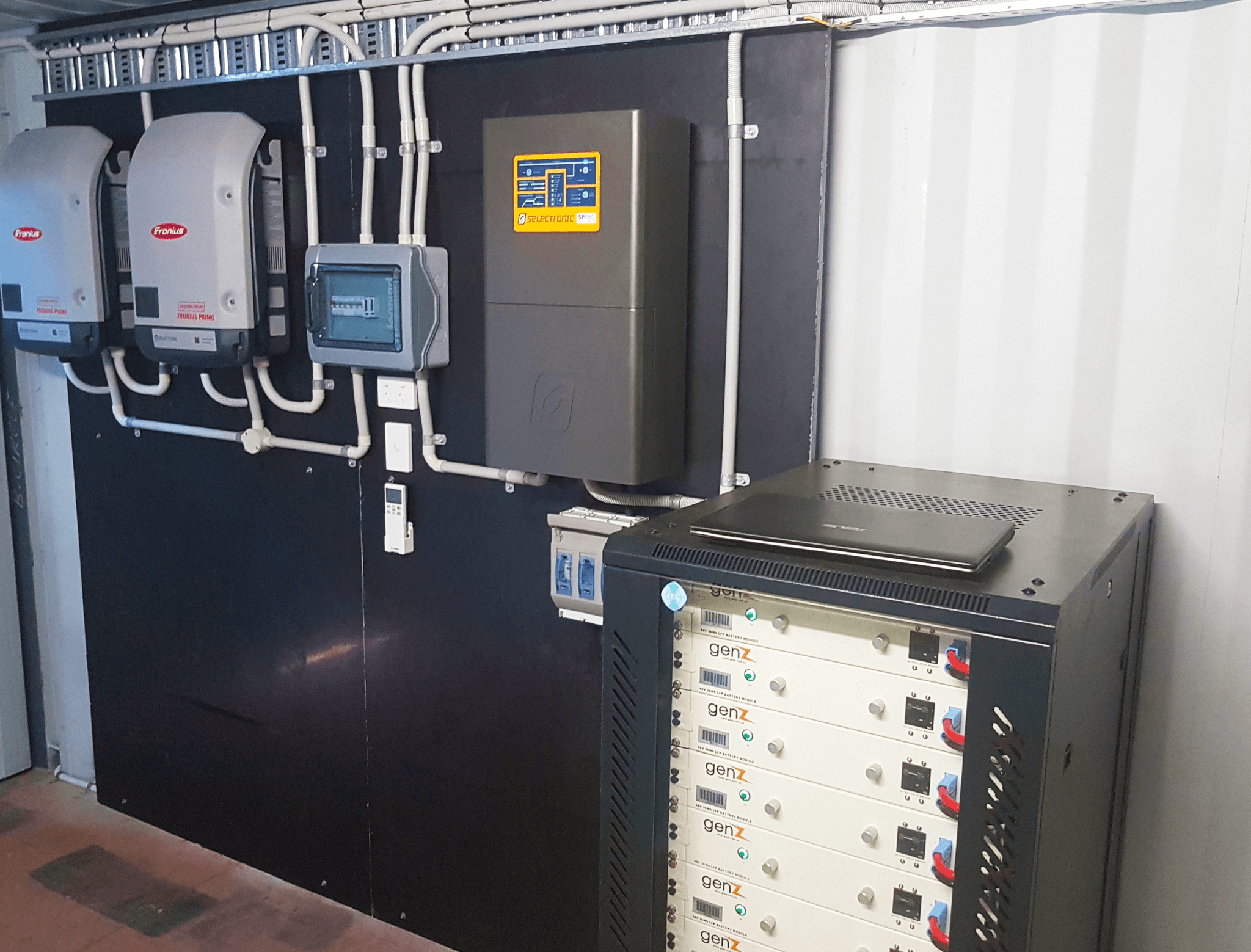

Title Image source: GenZ